DispersingWide Separator Apex Mill / WAM

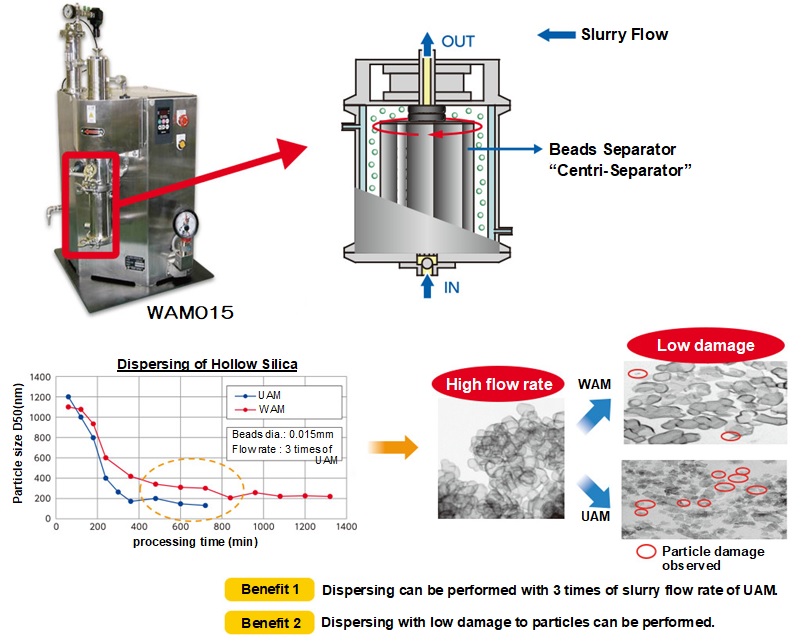

Wet type microbead mill applicable to dispersion of nanoparticle with high flow rate or with highly viscous slurry using microbeads.

Overview

This model is a wet-type bead mill with an enlarged multi-blade rotor that has functions of both agitation and bead separation. It handles microbeads of minimum size φ15μm.

Adopting the long multi-blade rotor, cross-section area for bead separation is 3 to 5 times larger than that of ordinary bead separators. Thus, this model has a large capability for bead separation, handling a high flow rate 3 times the flow rate of other models. It processes slurries with high viscosities as high as 2,000 m Pascal second even using microbeads.

Since the rotor is uniformly shaped along the vertical direction, it provides highly uniform agitating force throughout the whole mill, resulting in homogeneous dispersion and reduction in crystal damage. In addition, thanks to increase in number of passes per unit time due to the high flow rate, size distribution of the particles of this model is sharper.

Features

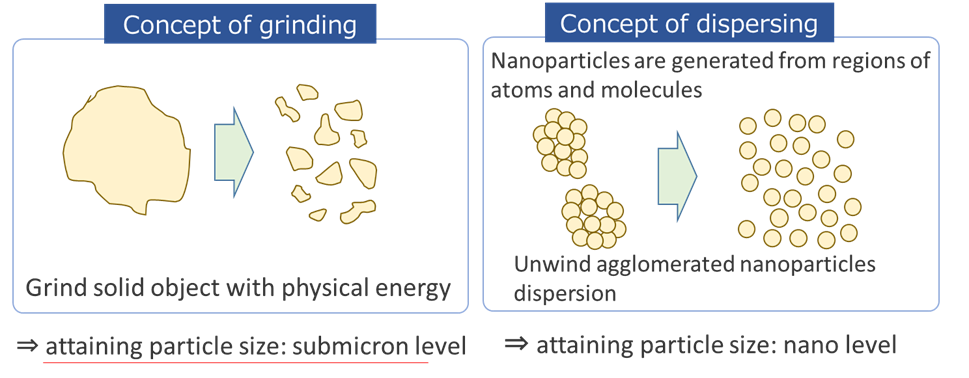

- 1. Submicron to nano-size dispersion processing with microbeads!

- This model is capable of dispersing slurry with fine particles of minimum 20nm by using microbeads of 15 μm to 100 μm.

- 2. Highly uniform dispersion processing is achieved in a short time!

- This model achieves uniform dispersion processing by using a high flow rate, which increases number of circulating passes per unit time greatly, and by the uniform agitation force induced by the multifunctional rotor. As a result, dispersion with a sharp particle size distribution is obtained, and gelling of slurry is prevented.

- 3. Micro-beads can also be used in high-viscosity slurries!

- With the use of a rotor for both stirring and separation greatly improves the bead separation capacity by expanding the passage area of the bead separation section. Dispersion of high viscosity slurries like several hundreds to 1000 MPa are available.

- 4. Easy disassembly maintenance and slurry recovery!

- Since this model is a vertical bead mill and of a simple structure as well as UAM, it is easy to disassemble the parts and to recover residual slurry in the mill.

Structure

Operating condition

- Applicable bead diameter

- Φ15μm〜Φ0.3mm

- Bead separator circumferential speed

- 6m/s〜12m/s

Application and final product examples

Electronic materials (barium titanate, hollow silica), electrode materials (nano silver, etc.), heat-blocking materials (ITO, etc.), photocatalysts (titanium oxide), liquid crystal pigments, battery materials, pharmaceuticals, pesticides, etc.

Main specification of the Wide separator Apex Mill

| Model | Inner Volume (L) |

Drive Motor (kW) |

Approx. Dimensions (m) | Approx. Weight (kg) |

||

|---|---|---|---|---|---|---|

| Length (m) |

Width (m) |

Height (m) |

||||

| WAM-015 | 0.15 | 2.2 | 0.6 | 0.48 | 0.85 | 100 |

| WAM-05 | 0.5 | 3.7 | 1.10 | 0.65 | 1.40 | 200 |

| WAM-1 | 1 | 5.5 | 1.10 | 0.80 | 1.75 | 350 |

| WAM-2 | 2 | 7.5 | 1.10 | 0.80 | 2.10 | 450 |

| WAM-5 | 5 | 15 | 1.25 | 0.80 | 2.10 | 550 |

| WAM-10 | 10 | 22 | 1.40 | 0.85 | 2.20 | 700 |

| WAM-30 | 30 | 55 | 2.10 | 1.45 | 3.00 | 2700 |

Lineup of Apex Mill Series

| Products | Summary | Applicable beads size |

|---|---|---|

| Apex Mill | Bead mill for grinding Vertical type bead mill for grinding particles of micron to submicron. |

φ0.3mm~φ5mm |

| Ultra Apex Mill | World`s first microbead mill Standard model of microbead mills for nano-grinding and nano-dispersion using microbeads, min. dia. 0.015mm |

φ15μm~φ1mm |

| Dual Apex Mill | Biaxial microbead mill This microbead mill is sued for nano-dispersion especially with low crystal damage. |

φ15μm~φ1mm |

| Wide Separator Apex Mill | Bead mill capable for high flow rate and with highly viscous slurry Microbead mill capable for dispersion nanoparticles at a high flow rate and/or with high viscosity. |

φ15μm~φ0.3mm |

| Ultra Apex Mill Advance | Ultimate low damage nano disperser Microbead mill providing a proper condition for nano dispersion with super low crystal damage. |

φ15μm~φ0.3mm |