DispersingUltra Apex Mill Advance / ADVPatented Technology

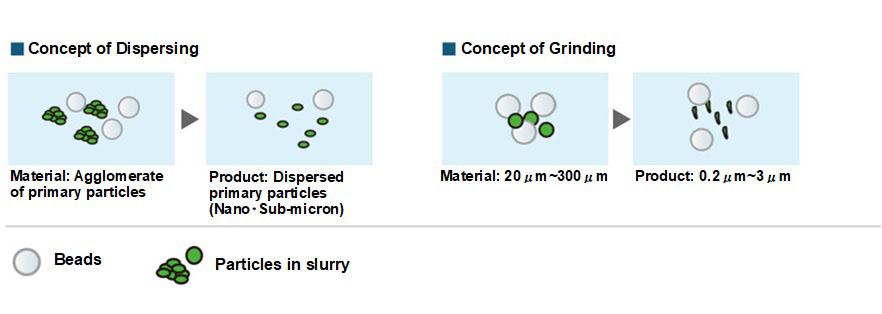

The ADV is a bead mill pursuing ultimate low damage nano dispersion. This model is particularly effective for low damage dispersion of soft nano-particles.

Overview

The ADV is a bead mill with an integrated rotating part consisting of special rotor/separator. This type is an extremly low damage bead mill that pursues uniformity and low damage (low centrifugal force). The ADV realizes nano-particle dispersion, which a conventional bead mill has difficulties performing due to particulate fracture. It enables dispersion without impairing the original physical properties of the particles. The ADV is an even further developed model of the DAM and WAM that pursues low damage processing.

Characteristics

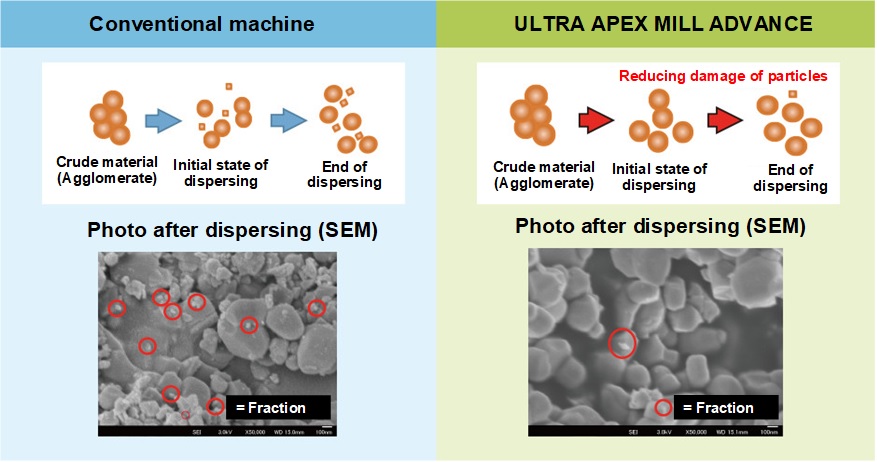

- 1. The ADV realizes dispersion with low damage to particles.

- By decreasing the centrifugal force, ADV can minimize particle damage. This enables reaggregation suppression and a slurry viscosity increase/gelling resulting from particulate fracture. The ADV is a model that further improves the DAM’s low damage processing performance and the WAM’s uniform processing performance.

- 2. The ADV realizes highly uniform dispersion processing.

- The ADV is equipped with a rotor that reduces the velocity distribution of the beads and suppresses slurry drift. It, therefore, realizes dispersion with an extremely sharp particle size distribution. This model is applicable to advanced processing of organic pigments and electronic materials.

- 3. The ADV can reduce contamination.

- The ADV can reduce the collisional energy between beads through low centrifugal operation and suppress bead wear. This leads to a reduction in bead contamination in the slurry.

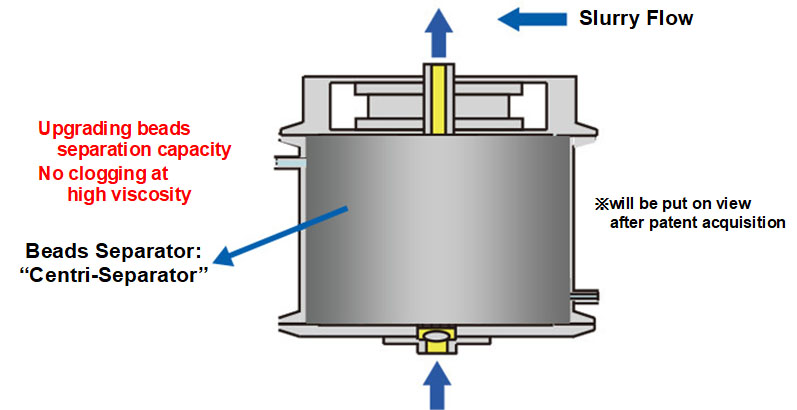

Structure

| Viscosity[mPa•s] | 500 | 700 | 1,000 | 2,000 |

|---|---|---|---|---|

| Ultra Apex Mill Advance |

◯ | ◯ | ◯ | ◯ |

| Conventional Mill [UAM] | ◯ | × | × | × |

Operation is possible even with four times the viscosity of a slurry processed using a conventional machine.

Operating condition

- Applicable bead diameter

- Φ0.015mm〜Φ0.5mm

- Bead separator circumferential speed

- 6m/s〜18m/s

Application and end product examples

High ViscosityOptical material (nano dispersion of zirconia/silica in resin raw material), Conductive coating material, cosmetics (dispersion of titanium oxide/zinc oxide in oil), etc.

Dispersing with low damageElectronic materials (such as titanate, hollow silica), electrode materials (such as nano silver, nickel), heat ray blocking materials (such as ITO), photocatalyst (titanium oxide), pigment for LCD color filter, etc.