Grinding/DispersingDual Apex Mill / DAM

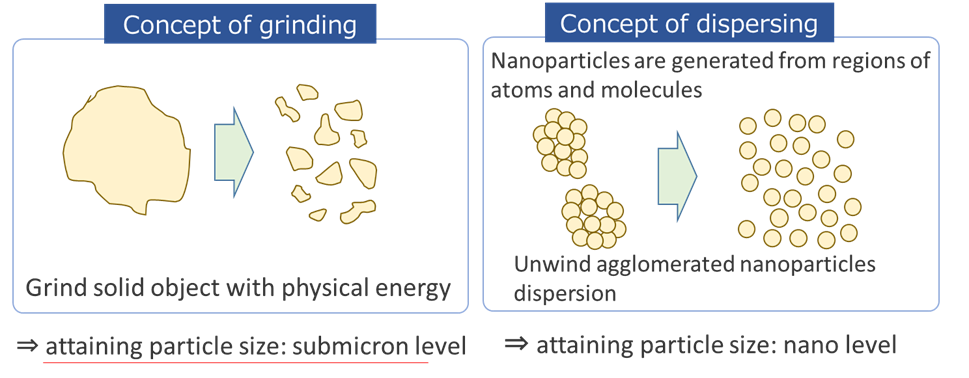

Wet type microbead mill for grinding and nanoparticle dispersion, especially for dispersing nanoparticles with low crystal damage.

Overview

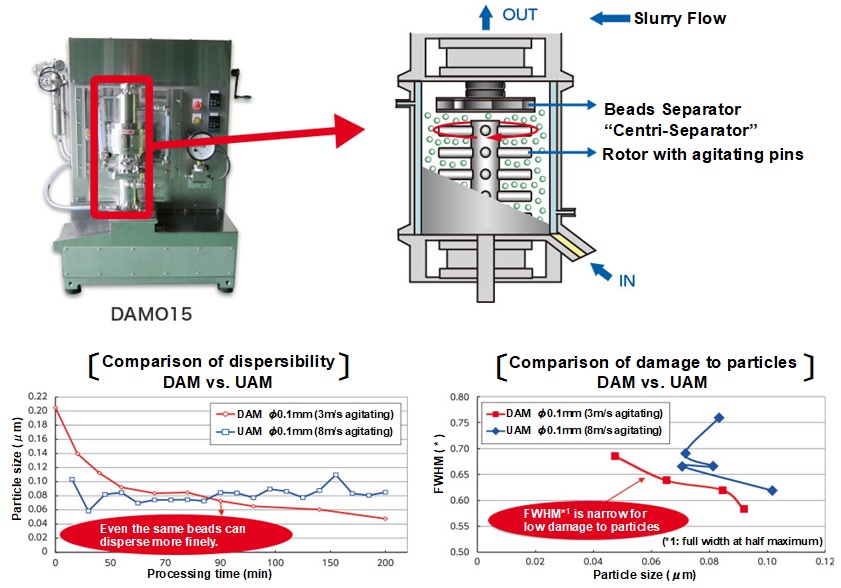

Dual Apex Mill (DAM) is a dual-axial wet type bead mill equipped with a centrifugal bead separator and an agitating rotor, which are driven independently, with a high flexibility in the agitating rotor revolution.

For low crystal damage on nanoparticles, it is necessary to rotate the agitating rotor at a low speed and to use microbeads at the same time. However, the slow rotation results in decrease in centrifugal force, and therefore, bead leakage easily occurs. Dual Apex Mill solves this problem by adopting a dual-axial system of driving the agitation rotor and the bead separator independently. The dual-axial mechanism allows a low speed agitation and a highspeed bead separation at the same time, so that nanoparticles are dispersed with a low crystal damage by applicating microbeads and slow rotation of the agitating rotor. As this model has a large freedom of the agitating rotor’s rotational speed, it is possible to rotate the agitating rotor at high speed too. Thus, this model is applicable for micron size grinding too. High power for grinding and moderate power for nano dispersion are handled by a single mill.

Two models available are a single motor coaxial type for mass production, which does not require seldom speed change, and a double driving axil type for operation requiring frequent speed change.

Features

- 1. Microbead processing of grinding and dispersion of submicron to nano-size particles are available!

- Dual Apex Mill is capable of dispersing slurry with fine particles as fine as 20 nm, because the applicable beads size of 15 μm in dia. at finest can be used.

- 2. Low speed agitation of Dual Apex Mill allows dispersion of nanoparticle slurry without significant crystal damage!

- As the agitating rotor and the bead separator are driven independently, microbeads do not leak even at a low agitating speed. The mill is applicable to nanoparticle dispersion that requires low damage agitation on particles of size from 20 to 300nm. This model is an ideal model for dispersing barium titanate, titanium oxide, pigments, etc., which require to avoid crystal damages.

- 3. Dual Apex Mill provides multiple purposes for slurry processing! An optimum bead mill for laboratory work!

- Dual Apex Mill handles a wide range of bead diameters from φ15 μm to 0.8mm and rotate agitating rotors at high speeds as well as low speed. It is also applied to grinding practice of micron size particles. Thus, a single mill of DAM deals with strong grinding and low crystal damage dispersion. Many customers have purchased this model as an experimental bead mill for multi-functional uses.

Structure

GlossaryHalf-value width is half the height of the peak value of the X-ray diffraction pattern. If the half-value width is narrow, the particles undergo low damage.

Operating condition

- Applicable bead diameter

- Φ0.015mm〜Φ0.5mm

- Bead separator circumferential speed

- 6m/s〜12m/s

- Dispersion rotor circumferential speed

- 2m/s〜12m/s

Application and final product examples

Electronic materials (barium titanate, hollow silica), electrode materials (nano silver, etc.), heat-blocking materials (ITO, etc.), photocatalysts (titanium oxide), liquid crystal pigments, etc.

Main specification of the Dual Apex Mill.

| Model | Inner Volume (L) |

Drive Motor (kW) |

Approx. Dimensions (m) | Approx. Weight (kg) |

||

|---|---|---|---|---|---|---|

| Length (m) |

Width (m) |

Height (m) |

||||

| DAM-015 | 0.15 | 2.2 | 0.60 | 0.65 | 1.00 | 250 |

| DAM-1 | 1 | 3.7 | 1.50 | 0.80 | 1.90 | 400 |

| DAM-5 | 5 | 7.5 | 1.50 | 1.20 | 2.35 | 750 |

| DAM-10 | 10 | 11 | 1.50 | 1.20 | 2.65 | 850 |

Lineup of Apex Mill Series

| Products | Summary | Applicable beads size |

|---|---|---|

| Apex Mill | Bead mill for grinding Vertical type bead mill for grinding particles of micron to submicron. |

φ0.3mm~φ5mm |

| Ultra Apex Mill | World`s first microbead mill Standard model of microbead mills for nano-grinding and nano-dispersion using microbeads, min. dia. 0.015mm |

φ15μm~φ1mm |

| Dual Apex Mill | Biaxial microbead mill This microbead mill is sued for nano-dispersion especially with low crystal damage. |

φ15μm~φ1mm |

| Wide Separator Apex Mill | Bead mill capable for high flow rate and with highly viscous slurry Microbead mill capable for dispersion nanoparticles at a high flow rate and/or with high viscosity. |

φ15μm~φ0.3mm |

| Ultra Apex Mill Advance | Ultimate low damage nano disperser Microbead mill providing a proper condition for nano dispersion with super low crystal damage. |

φ15μm~φ0.3mm |