Dispersing/EmulsifyingApex Disperser ZEROPATPEND

Apex Disperser ZERO, a multifunctional media free mill for:

“dispersion/defibrating of slurries with soft particles and highly viscous slurries”,

“continuous emulsification”,

“mixing/dispersing processing without bead contamination”, and

“continuous mixing of highly viscous slurries”.

This model can meet such requests and offers multifunctional beadless dispersing/mixing as previously stated.

Overview

Apex Disperser ZERO is a multifunctional media-less apparatus capable of emulsifying, mixing, kneading, dispersing, and defibrating by applying high shear force to slurry. Note ZERO is named after “a high shear mill with Zero media”.

The apparatus consists of a rotor and a stator, which form a very narrow shear gap between them. Highspeed rotation of the rotor induces a high shear force in the gap. Slurry introduced into the mill passes through the gap, receiving strong, homogeneous shear force in a very short time, say under 1 second. In addition, since all slurry pass through the gap evenly, the enter slurry is uniformly mixed or emulsified even by a single pass. Thus it is easy to produce small lot products.

By only changing operating conditions such as changing the rotor peripheral speed, “ZERO” can cover the dispersion of low damage to particles and the realization of strong dispersion force with a single machine.

Features

- 1.“ZERO” copes with multiple processes of emulsification, mixing, kneading, dispersion, and defibration!

- Various processes can be handled by only changing the operating conditions. “ZERO” can easily construct optimum operating conditions for a variety of prescriptions, and it is able to proceed with the development of a wide variety of products. In addition to the emulsification, it can process low damage dispersion, solid-liquid/liquid-liquid mixing, and defibrillation and mixing of nanofibers like carbon nanotubes (CNTs), cellulose nanofibers (CNFs), etc.

- 2.“ZERO” enables homogeneous emulsification, dispersion, and mixing!

- All slurries fed into the machine pass through high shear crevices subjected to homogeneous shear forces, so homogeneous processing is available in just one pass. It can treat homogeneous emulsions, micelles, and pastes in a short time, and can process large quantities with small equipment. Compared to batch emulsion kettles, which are prone to uneven shear force, “ZERO” can produce a homogeneous slurry. In addition, the slurry temperature can be controlled by adjusting the processing conditions.

- 3.Slurry with a variety of physical properties can be produced by one unit!

- It is easy to respond to a wide variety of materials and to produce a wide variety of small lots by changing operating conditions without changing parts. Utilization as an experimental laboratory machine enables rapid product development.

- 4.Benefits of continuous sealed processing can be enjoyed!

- ①The optimum operation method can be selected according to the processing purpose.

One-pass continuous processing (connectable to upstream and downstream equipment in a sealed state), circulation processing, two-liquid or three-liquid simultaneous supply processing, etc.

②Treatment of high viscosity slurry is available.

Sealed treatment enables dispersing or defibration of high viscosity slurry applicable for even 100,000mPa・s. - 5.The ZERO is easy to maintain!

- Because “ZERO” is a beadless mill and has an integrated structure, it is easy to disassemble and clean the machine. In the treatment of cosmetics and foodstuffs that require hygienic considerations, cleaning treatment is ensured, and the workload can be greatly reduced. “ZERO” can get rid of the troublesome operations of bead washing and bead control.

- 6.“ZERO” can solve the problem of the three-roll mill!

- The following problems can be solved by replacing the three-roll mill. Improvement of workplace safety and health issues, such as entanglement in rolls during work and deterioration of work environment while using solvents. In addition, elimination of very skilled operation such as clearance adjustment between three-roll can be solved.

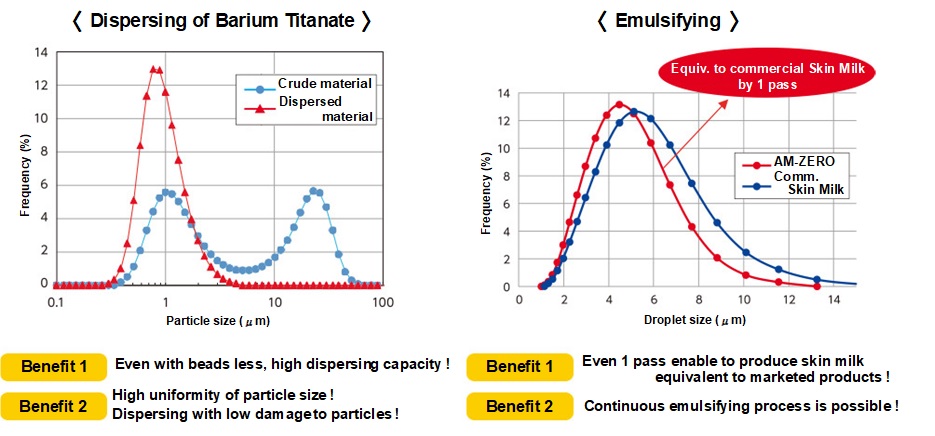

Performance Data

Application and final product examples

Dispersing: Thick film electrode materials (gold, silver, platinum, vanadium, etc.), Semiconductor encapsulant (silica in resin etc.), etc.

Defibrating: Carbon nanotube, Cellulose nanofiber

Mixing: Battery material (mixture of positive electrode material, carbon, and binder), etc.

Emulsifying: Cosmetic (skin milk), toiletry, food, synthetic rubber (latex), etc.

*For further queries, please contact our sales representatives.