CentrifugationScreen Bowl Centrifuge / SVS

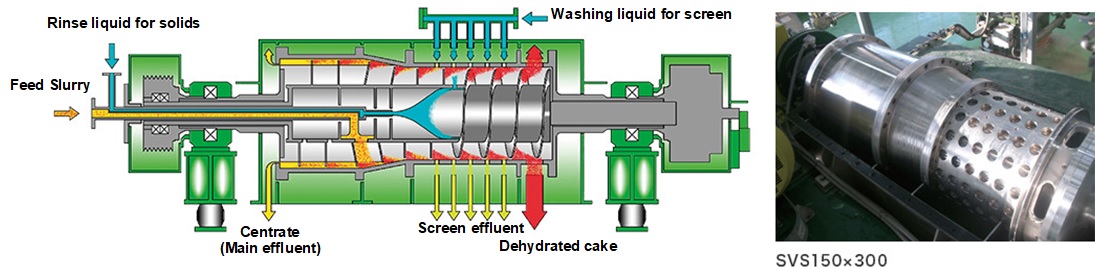

The Screen Bowl Centrifuge is a centrifuge optimized for separation, classification, and dehydration of slurry containing crystalline solids.

Overview

This centrifugal is a decanter type centrifugal with a screen in the bowl near the discharging side for lowering the water content. This model is applied to incompressible particles, such as coal powder and inorganic crystals.

Characteristics

- 1. Extremely low water content results from the doubling effect developed through centrifugal separation and

screen filtration.

In addition, large-capacity processing is possible. - 2. Low driving power and wear

- Operation under a low rotation speed is possible thanks to the extremely highdewatering capacity.As a result, mechanical wear is reduced.

- 3. Simultaneous washing of crystalline material is also possible.

- Crystalline washing performance is excellent because of the rinse liquid spray over the screen segment. This leads to a reduction in the process time.

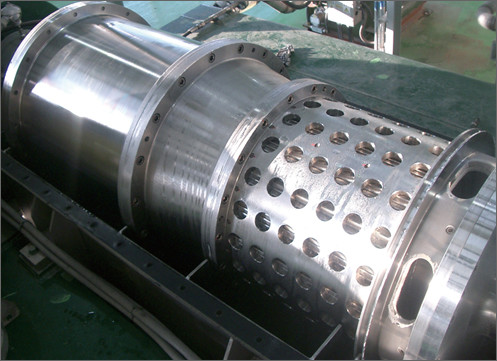

Structure

- Major portion of liquid in the supplied crude slurry is separated by centrifugal force in the first stage. The liquid separated from the solid is discharged from holes on the feeding side end of the bowl.

- The solid on the inner face of the bowl is conveyed to the conical zone. Then it is lifted up from the liquid pool on the bowl and turns in a condensed form.

- The condensed solid is further dewatered during it is conveyed on the screen part of the bowl. Then it is discharged from the bowl.

- The particles are washed by spraying rinsing water on them on the screen section of the bowl, when rinsing treatment is needed.

Centrifuge lineup

| Model | Drive Motor | Approx. Weight (kg) | Approx. Dimensions (mm) | ||

|---|---|---|---|---|---|

| Length | Width | Height | |||

| SVS150×300 | 3.7 〜 5.5 | 1300 | 1500 | 1400 | 750 |

| SVS450×700 | 22 〜 45 | 3500 | 2560 | 2130 | 1085 |

| SVS450×1000 | 22 〜 45 | 4500 | 2840 | 2130 | 1085 |

| SVS600×1000 | 30 〜 75 | 5400 | 3025 | 2400 | 1260 |

| SVS600×1500 | 37 〜 90 | 8500 | 3700 | 2400 | 1260 |

| SVS600×2500 | 37 〜 90 | 13500 | 4570 | 2400 | 1260 |

| SVS800×1300 | 55 〜 132 | 13200 | 4050 | 3150 | 1640 |

| SVS800×1700 | 55 〜 132 | 15300 | 4200 | 3000 | 1640 |

| SVS900×1800 | 75 〜 160 | 15500 | 4260 | 3000 | 1640 |

| SVS900×2500 | 90 〜 160 | 19000 | 5000 | 3000 | 1640 |

| SVS1100×2600 | 110 〜 200 | 21000 | 5460 | 3000 | 1700 |

| SVS1100×3300 | 110 〜 250 | 25000 | 6160 | 3000 | 1700 |

| SVS1400×1800 | 110 〜 250 | 21500 | 5485 | 3000 | 1895 |