CentrifugationPusher / SP

Centrifugal filter, dehydrating and rinsing without crystal fracturing

Overview

Pusher™ is a centrifugal filter equipped with two cylindrical baskets that are horizontally installed on a single driving shaft. Metal screens for separating liquid and solids are mounted inside the baskets. Slurry with crystals or pellets is firstly fed on the inner face of the inner (smaller) basket. The solids placed on the screens are pushed to the outer (lager) basket by oscillation of the inner basket. They are thoroughly dehydrated and discharged from the outer basket in a short time. It is possible to minimize damages on the solids, since the inner basket oscillates with a short stroke. Thus, this model is ideal for treatment of fragile crystals and pellets to avoid their damages. In addition, when processing hard crystals, wears of the screens and the conveying parts are lower than those of other filters, resulting in stable processing and longer maintenance periods.

This model is also available for washing solids form impurities by showering clean water or rinsing solution during the solids moving on the screens. It, therefore, has a function of dewatering and washing solids simultaneously. This model is best fit to dehydration and rinsing of resin and nylon pellets, ammonium sulfate, inorganic and organic salts, etc.

Features

- 1. High-speed dehydration by high centrifugal force

- Low moisture content is achievable in 5 or 10 seconds by applying centrifugal force as high as 600 G. This model is a compact and highly productive dehydrator for crystals and pellets.

- 2. Dehydration with low particle damage

- The solid conveying mechanism of this machine provides minimized damages on the particles due to the moderate motion of the solids on the screen by short stroke oscillation of the inner basket. The damage of the solids is minimized since the solids is pushed as a bulk. This model is suitable for dehydrating and washing soft particles, black sesame seeds for example, fragile salts, etc.

- 3. Effective crystal washing

- Impurities adhering to particles are washed off by showering clean water or rinsing solution on the particles after the primary dewatering is performed. When the particles drop from the inner basket to the outer one, the particles are well agitated. The particles near the screen, which are not well washed, are exposed on the surface of the bulk. Thus, the particles are washed quickly and completely.

- 4. Long life of the screen and the conveying parts even with hard crystal treatment

- Frictions acting on the screen and the conveying parts are low as the direction of oscillation of the inner basket is vertical to the face of the basket end. The low friction results in reduction in wear of the conveying parts and the screen largely. In addition, the wedge wire screen applied to this model has excellent wear resistance. Thus, this model is durable for hard crystal dehydration.

- 5. Easy maintenance and low running cost

- Few mechanical parts require periodical maintenance, and they last long. In addition, due to its simple mechanical structure, the machine is easily maintained on the installation site. Thus, the maintenance work is performed in a short time and at low cost.

Structure and Mechanism

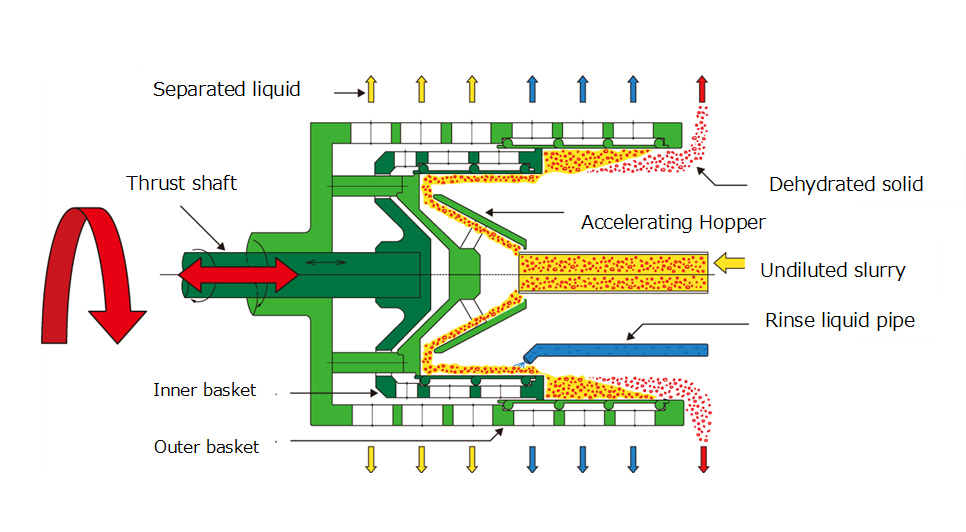

This machine is equipped with a pair of rotating baskets, inner (smaller) and outer (larger). Wedge wire screens are installed inside the baskets. Slurry is fed to the accelerating hopper via the feed pipe and is carried to the inner basket. Then the particles in the slurry are scattered on the screen and instantly dehydrated. After then, the particles overflow from the inner basket on the outer basket. The inner basket oscillates in the axial direction. This motion helps particles’ move of the overflowing and pushes the particles on the outer basket towards the basket end. During the particles move on the screens, they are dewatered rapidly. In addition, when rinsing treatment is needed, impurities adhering to the particles are washed out by spraying a rinsing solution.

Application example

| Food stuff | Organic chemicals | Inorganic chemicals |

|---|---|---|

| ・Cooking salt | ・Nylon pellets | ・Ammonium sulphate |

| ・Amino acids | ・Fluorine rubber | ・Sodium sulphate |

| ・Cellulose | ・Polystyrene | ・Sodium formate |

| ・glycine | ・ABS resin | ・Sodium carbonate |

| ・Arginine | ・SA resin | ・Soda metasilicate |

※In addition, it is suitable for separation-dehydration of a broad range of solid particles of 0.1 mm or more. Please feel free to contact us if you have any questions.

Standard Specifications

| Model | Nominal Capacity (m³/h) |

Motor power | Centrifugal G Effect (G) |

Approx. Weight (kg) |

Approx. Dimensions (mm) |

|||

|---|---|---|---|---|---|---|---|---|

| Main | Hydraulic | Length | Width | Height | ||||

| SP250 | 2.5 | 5.5 | 2.2 | 600 | 700 | 1750 | 900 | 1000 |

| SP350 | 4.5 | 7.5 | 3.7 | 600 | 900 | 1850 | 1040 | 1050 |

| SP450 | 8 | 15 | 7.5 | 600 | 1800 | 2200 | 1300 | 1330 |

| SP600 | 15 | 22 | 11 | 600 | 3000 | 3400 | 1560 | 1570 |

| SP800 | 25 | 45 | 18.5 | 600 | 4000 | 3600 | 1850 | 1920 |