Concentration/WashingRotary Filter / RF

High-speed sealed filter using the cross flow filtration principle

Overview

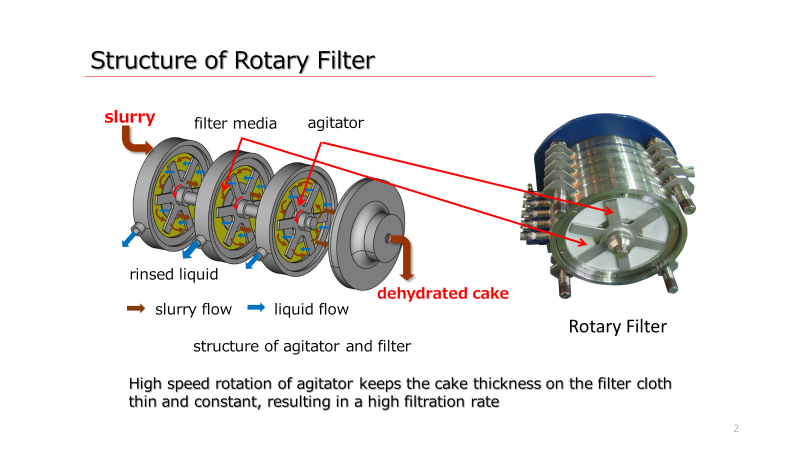

Rotary Filter is operated based on the cross flow filtration principle. Since the slurry flow is parallel to the filter media surface, while the pressure gradient is perpendicular, the cake layer on the filter media surface is peeled off and kept thin. Thus, the filtration speed is kept high for a long time.

Rotary Filter is a sealed filter apparatus that realizes the cross flow by a mechanism of agitating plates rotating adjacent to the filter media surface. The plates form a faster slurry flow than the conventional cross flow filtration. Thus, highspeed filtration is available even with highly concentrated slurry. It is available to filter slurry containing particles of size from submicron to micron, and also to filter a difficult-to-filtrate slurry.

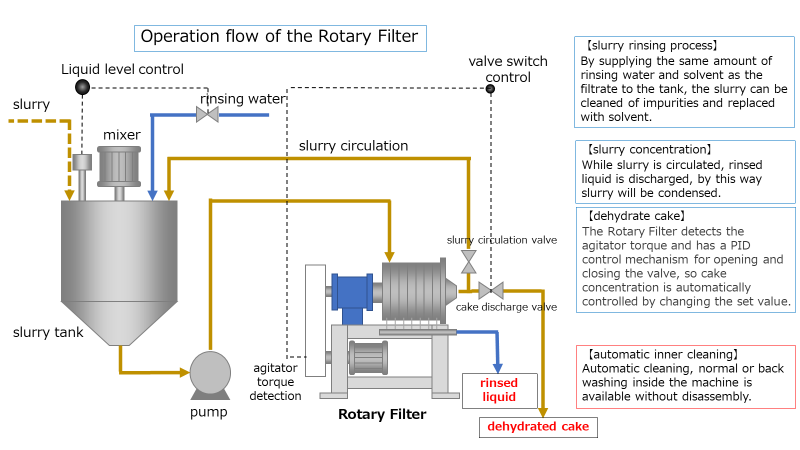

Rotary Filter is a pressurized sealed filter that enables continuous discharging of condensed slurry or cake and is especially effective when it is applied to continuous dehydration, rinsing, and solvent replacement. In addition, the cake concentration is automatically controlled by detecting torque of the agitators, which is determined by the concentration.

Another type of the series, Ceramic Rotary Filters, is lined up for nanoparticle filtration.

Features

- 1.Consistent filtration rate is obtained at high filtering rate over a long period of time!

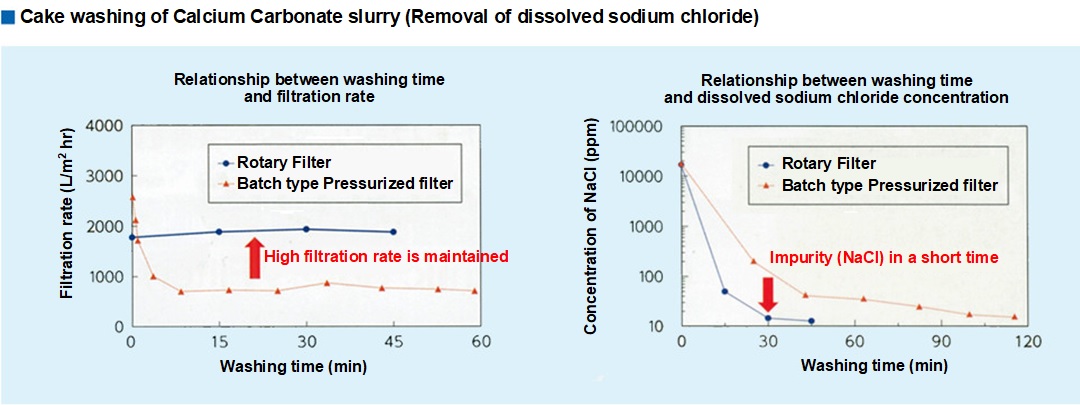

- In Rotary Filter, the cake thickness on the filter media is controlled thin and constant, resulting in a high filtration rate maintained for a long time. In addition, as the concentrated cake is discharged continuously, the filter does not require time for cake recovering and filter media rinsing. Thus, the valid time rate is higher than other filtering processes and, as a result, the overall filtering capacity is high.

- 2.Difficult-to-process slurry is filtrated!

- As Rotary Filter is a sealed filtration apparatus, it stably filters slurries even with volatile, acid and alkaline solvents. An optional model that is resistant to acid and alkali is available. In addition, thanks to effect of the cross flow adjacent to the filter media surface, viscous or concentrated slurry and slurry that are unstable for other filters are processable.

- 3.Condensing, Rinsing, and Solvent Replacing Processes are efficiently implemented!

- Rotary Filter is effective in filtrating various types of slurry processing owing to the highspeed filtration and the mechanism of continuous cake discharging. Thus, it provides high performance especially for rinsing and solvent replacement, resulting in significant time saving. A closed filtering apparatus of Rotary Filter configurates a simple filtering system.

- 4.Continuous filtering process, automation and no-man operation are materialized, since filtration is performed in a sealed chamber!

- As the filtrate and the concentrated cake are recovered continuously and filtering is performed in a pressurized chamber, this filter can be connected to upstream and downstream equipment in a sealed state. In addition to this feature, owing to the automated control of cake concentration, automatic and no-man operation is applicable. The total system of filtering in a sealed state materialized by Rotary Filter is effective in preventing contamination of products and dirt deposit due to scattered cakes; working environment is greatly improved. Particularly, labor saving effect for handling of the recovered cake and cleaning work is significant.

- 5.Large sized machines are also available!

- Large sized filters installing large filter plates in multiple stages are lined up for mass processing. The largest filtration area is 30㎡.

Structure

Simplified chart of sealed automatic continuous filter

| Type | Rotary Filter【RF】 |

|---|---|

| Applicable Particle Size |

Fine particles sub-micron to 100 μm |

| Processing Mode | rinsing, concentration, dehydration, and solvent replacement |

| Filter Media | Cloth |

| Filtration Rate | 200 〜 2000 L/㎡hr |

| Applications |

|

Main specifications of Rotary Filter

| Model | Filtration Area (m²) |

Drive Motor (kW) |

Approx. Dimensions (m) | Approx. Weight (kg) |

||

|---|---|---|---|---|---|---|

| Length | Width | Height | ||||

| RF-02 | 0.18 | 3.7 | 0.95 | 0.60 | 0.95 | 550 |

| RF-1 | 1 | 5.5〜7.5 | 1.50 | 0.80 | 1.20 | 750 |

| RF-2.5 | 2.5 | 11〜15 | 1.70 | 0.90 | 1.40 | 1200 |

| RF-5 | 5 | 22〜30 | 2.00 | 1.30 | 1.60 | 1700 |

| RF-10 | 10 | 37〜45 | 3.20 | 2.00 | 1.40 | 3900 |

| RF-20 | 20 | 45〜55 | 3.50 | 2.30 | 1.95 | 5800 |

| RF-30 | 30 | 55〜90 | 3.90 | 2.40 | 2.10 | 8000 |