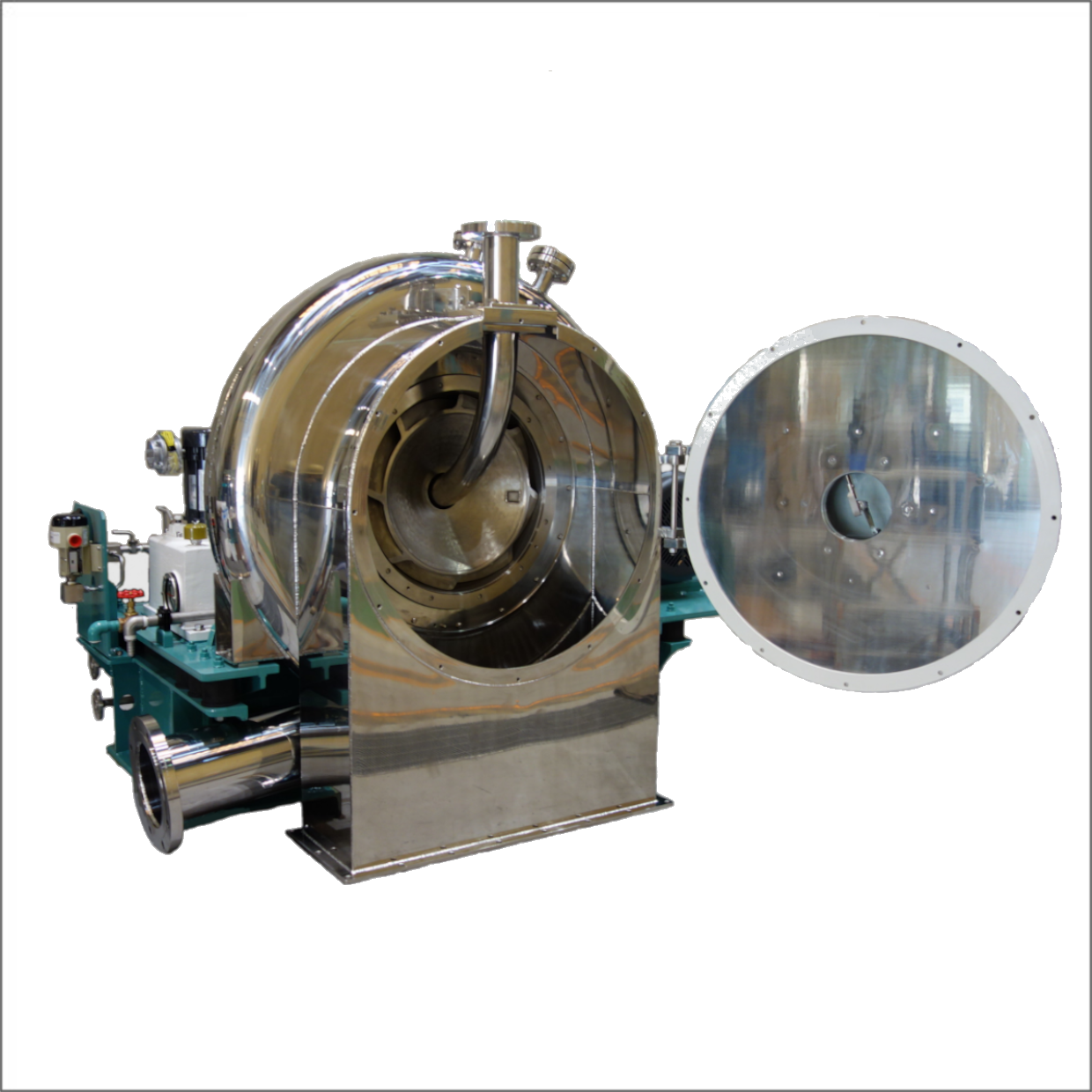

CentrifugationCentrus / N

Centrifugal filter, dehydrating particles in a second to get low water content!

Overview

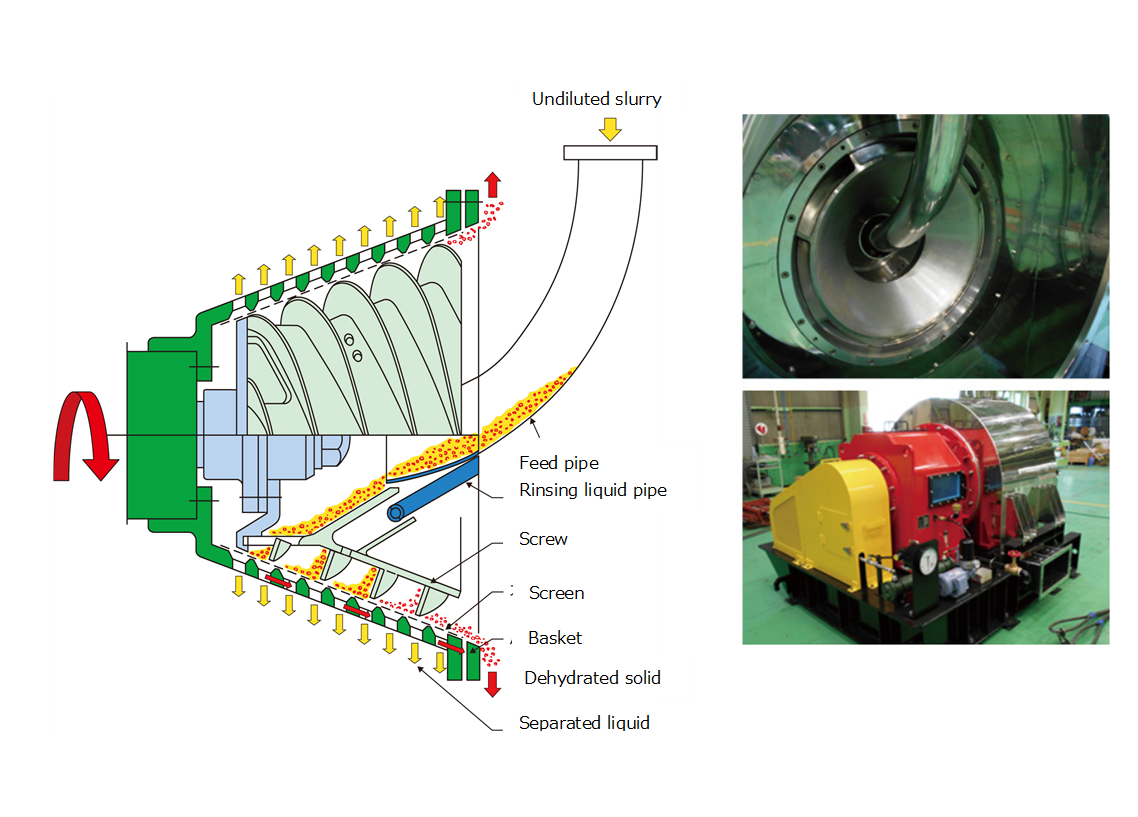

Centrus ™ is a centrifugal filter equipped with a conical basket and a screw discharger that are horizontally aligned on the driving shaft. A metal screen for solid separation is mounted inside the basket. Slurry casted onto the basket is instantaneously dehydrated by the high centrifugal force induced by rotation of the basket. Dewatered particles remaining on the screen are discharged with the discharger that is spirally shaped.

This model is also applied to rinsing practices. Impurities adhering to the particles on the screen are washed out by spraying clean water. The water with the impurities leaves the particles during they are transported on the screen. Thus, it simultaneously dehydrates particles and washes off impurities.

This model is applied to dewatering and cleaning precipitated crystals and resin pellets, such as sodium glutamate, amino acids, and inorganic salts, nylon pellets, larger than 0.1mm.

Features

- 1. High-speed dehydration by high centrifugal force

- Particles on the metal screen are filtrated by the high centrifugal force. Dehydration finishes in a short time, typically about 1 second. In case of dewatering cooking salt (NaCl), the finished moisture is 0.5-2%. Since the surface moisture of the crystal is mostly removed, drying process can be eliminated or heat load for drying is reduced.

- 2. Applicable to dehydration of highly elastic resin pellets

- The screw discharging mechanism produces almost no compression on resin pellets, so that even if they are elastic, they are not deformed or agglomerated. It is easy to dehydrate highly elastic resin pellets that easily lump up in centrifugal filters of other types.

- 3. Compact design, and saving space and energy

- This centrifugal filter is quite compact and highly productive, since the hydration finishes in an extremely short time. It is an ideal centrifugal filter for mass processing. As the conical basket is wide on the outside, the particles receive centrifugal force acting outwards, so that less power is needed to transfer the particles. As a result, the driving motor is downsized, and less power is needed.

- 4. Easy maintenance and low running cost

- Disassembly and assembly for the maintenance are simple and easy, since the mechanical parts are small and integrated. In addition, maintenance work is performed on installation site. Thus, maintenance costs are reduced.

Structure and Mechanism

Main parts of this filter consist of rotating parts, a basket, a discharging screw, and a metal screen. Stock solution or reactor slurry is supplied through the feed pipe to the center of the screw. The supplied slurry is transferred onto the screen, where the liquid is instantaneously separated from the solids. The solids are continuously conveyed to the solid outlet by the discharge screw, and then discharged.

Application example

| Food stuff | Organic chemicals | Inorganic chemicals |

|---|---|---|

| ・Cooking salt | ・Nylon chips | ・Ferrous sulphate |

| ・Monosodium glutamate | ・Fluorine rubber | ・Ammonium sulphate |

| ・Crushed corn meal | ・Polystyrene | ・Copper sulphate |

| ・Cellulose | ・ABS resin | ・Sodium sulphate |

| ・Amino acids | ・SA resin | ・Sodium formate |

| ・Polycarbonate | ・Sodium carbonate | |

| ・Polyurethane resin | ・Soda metasilicate |

※In addition, it is suitable for solid-liquid separation of particles of 0.1 mm or more. Please feel free to contact us if you have any questions.

Standard Specifications

| Model | Nominal Capacity (m³/h) |

Motor power | Centrifugal Effect (G) |

Approx. Weight (kg) |

Approx. Dimensions (mm) |

|||

|---|---|---|---|---|---|---|---|---|

| Main | Lubricating | Length | Width | Height | ||||

| N200 | 0.5 〜 1.5 | 3.7 | 1600 | 225 | 985 | 990 | 915 | |

| N250 | 1 〜 3.5 | 5.5 | 1600 | 560 | 1175 | 1135 | 1060 | |

| N320 | 3 〜 7 | 7.5 | 1600 | 700 | 1295 | 1165 | 1155 | |

| N400 | 5 〜 12 | 15 | 0.4 | 1600 | 1100 | 1690 | 1200 | 1425 |

| N520 | 10 〜 25 | 30 | 0.4 | 1200 | 2000 | 2160 | 1540 | 2160 |

| N700 | 20 〜 50 | 45 〜 55 | 0.4 | 1200 | 3000 | 2480 | 2160 | 2140 |