Concentration/WashingCeramic Rotary Filter / CRF

Rotating ceramic filter for concentration and rinsing of nanoparticle.

Overview

Ceramic Rotary Filter is a state-of-art filtering apparatus adopting ceramic filter media with ultrafine pores. It allows stable high-speed filtering of slurries containing nanoparticles by taking advantage of the cross flow filtration theory. A ceramic filter disk that is hollow inside is mounted to a rotating shaft in a sealed chamber. The filter disk rotates at high speed forming a flow parallel to the disk surface. The cake thickness on the ceramic filter disk is controlled thin and constant by the turbulent flow. As a result, filtration resistance of the filter disk is low and consistent, resulting in a high filtration rate maintained for a long time. The filtrate passed through the filter disk flows out through a channel of the hollow driving shaft. Concentrate or cake is discharged from the outlet on the end plate on the opposite side of the inlet. Models of large filtering areas are also lined up.

Ceramic Rotary Filter allows filtering of slurries with superfine particles, nano to submicron in size, since the filter disk has nanopores, 7 nanometers finest. It provides efficient treatments of slurries, such as concentration, rinsing, and solvent replacement. Taking advantage of effect of turbulence along the filter disk, difficult-to-process slurries, for example fibrous nanomaterials, are efficiently filtered.

The other type of the series, Rotary Filter, which is of a cloth filter type, is lined up for filtration of slurries with particles of size of micron to submicron.

Features

- 1.Efficient slurry filtration of nano-sized to submicron particles!

- Ceramic Rotary Filter, which utilizes advantages of nanopores of the filter disk and the cross flow technology combined, is a filtering apparatus applicable to process slurries with particles as fine as 30 nanometers. Fibrous nano materials, such as cellulose nano fiber and carbon nano tube, are also efficiently filtered.

| Pore Size | 2.0μm | 5.0μm | 0.2μm | 60nm | 30nm | 7nm |

|---|---|---|---|---|---|---|

| Material | Al2O3 | Al2O3 | Al2O3 | Al2O3 ZrO2 |

TiO2 | MgAl2O4 |

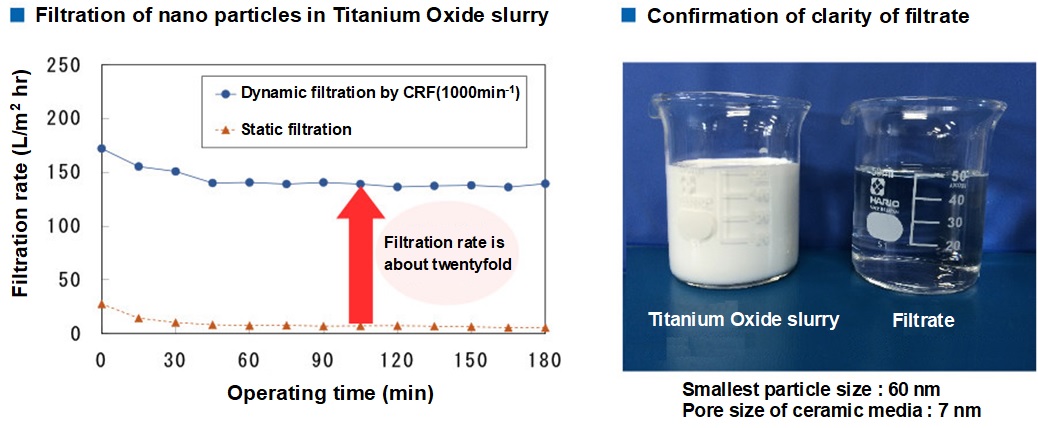

- 2.High filtering rate is stably kept over a long period of time!

- In Ceramic Rotary Filter, the cake thickness on the filter disk is controlled thin and constant by the cross flow filtering technology, resulting in a high filtration rate maintained for a long time. In addition, as the concentrate is discharged continuously, the filter does not require time for recovering cake and rinsing filter media. Thus, its valid time ratio is much higher than other filtering processes and, as a result, its overall processing capacity is very high.

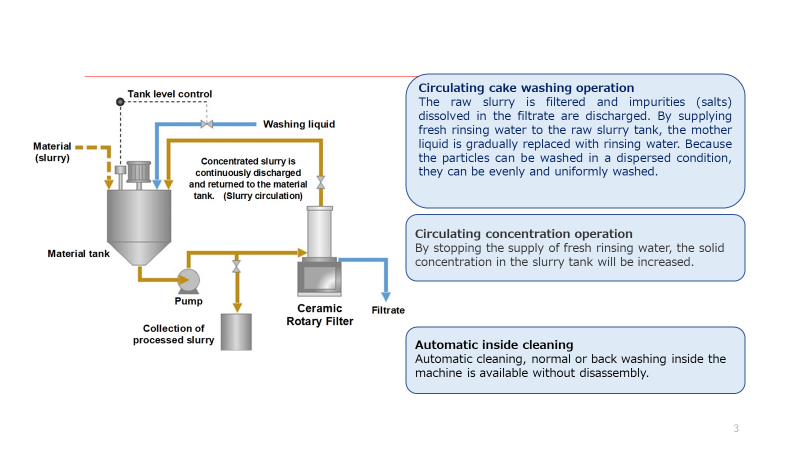

- 3.Ceramic Rotary Filter is applied to processes of concentration, rinsing, and solvent replacement of slurries are efficiently implemented!

- Ceramic Rotary Filter preforms effective filtrating operation with various types of slurry owing to the highspeed filtration principle and the mechanism of continuous concentrate discharging. Thus, it provides high performance especially for operations of rinsing and solvent replacement, resulting in significant time saving.

- 4.Continuous filtering, automated and no-man operation!

- As the filtrate and the concentrate are discharged continuously and filtering is performed in a pressurized chamber, Ceramic Rotary Filter provides a simple process configuration connecting it to upstream and downstream apparatuses in a closed state. In the closed processing system, benefits realized in Ceramic Rotary Filter are such advantages as avoiding contamination of products, reducing dirt deposit due to scattered cakes (working environment improvement), and omitting material handling work.

- 5.Large sized machines are also available!

- Models of large filtering area are lined up. Large filter disks are installed in these models. The largest available model has a 5㎡ filtration area for mass processing.

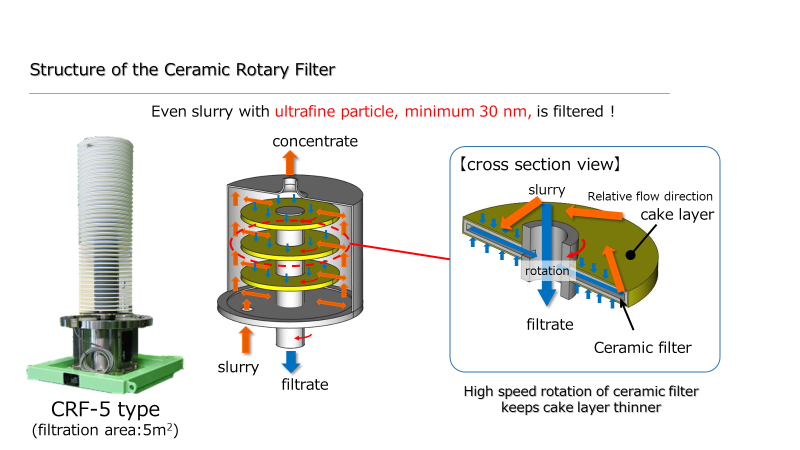

Structure

Ceramic filters set in the shaft rotate at a high speed in the filter chamber with a pressure resistant structure. The slurry is pressurized and fed from the supplying port. The concentrated liquid is collected and the clean filtrate filtered by the ceramic filters passes through the hollow inside the shaft and is discharged outside.

Operation Flow

Performance Data

Example: Nanoparticle filtration of titanium oxide (10 mass%) slurry.

Main specifications of Ceramic Rotary Filter

| Model | Filtration Area (m²) |

Drive Motor (kW) |

Approx. Dimensions (m) | Approx. Weight (kg) |

||

|---|---|---|---|---|---|---|

| Length | Width | Height | ||||

| CRF-0 | 0.03 | 2.2 〜 3.7 | 1.0 | 0.6 | 1.2 | 500 |

| CRF-1 | 1 | 3.7 〜 5.5 | 1.5 | 0.8 | 1.2 | 650 |

| CRF-2 | 2 | 3.7 〜 5.5 | 1.5 | 0.8 | 1.5 | 750 |

| CRF-5 | 5 | 7.5 〜 11 | 1.5 | 0.8 | 2.2 | 1200 |